Wide pore silica gel, also known as Type C silica gel, is a highly active adsorbent material that belongs to the category of amorphous substances. Its chemical molecular formula is mSiO₂·nH₂O. Due to its unique chemical composition and physical structure, wide pore silica gel possesses a variety of excellent properties and has been widely applied in many industrial fields.

Wide pore silica gel is insoluble in water and any organic solvents. It is non-toxic, odorless, and has excellent chemical stability, which is compatible with the performance requirements of octadecylsilyl silica gel column. Except when exposed to strong alkalis and hydrofluoric acid, wide pore silica gel generally does not react with other substances. Its key characteristics include:

High adsorption capacity

Good thermal stability

Chemical stability

High mechanical strength

These properties make wide pore silica gel indispensable in applications such as adsorption, drying, and catalysis.

Wide pore silica gel is mainly divided into three types:

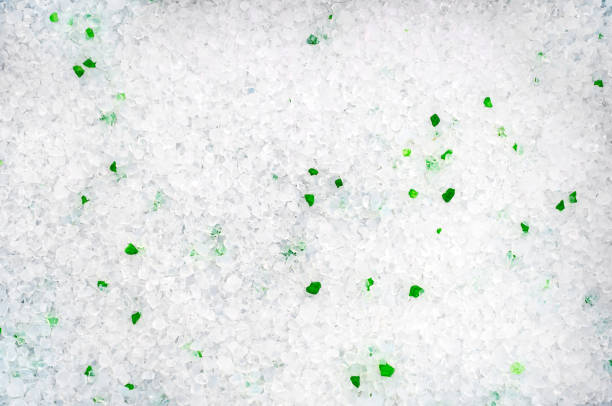

Block wide pore silica gel: White, glassy, irregular particles that may contain a few differently colored particles.

Spherical wide pore silica gel: White, frosted glass-like spherical particles, also allowing for the presence of a few differently colored particles.

Microspherical wide pore silica gel: Exists in finer particle forms, suitable for special process requirements.

Different forms of wide pore silica gel offer distinct advantages depending on the specific application scenario.

Wide pore silica gel is widely used in industrial production and gas purification processes, specifically in the following areas:

Catalysts and catalyst carriers: In the production processes of important industrial products like melamine, phthalic anhydride, maleic anhydride, butadiene, acrylonitrile, etc., wide pore silica gel is used as a catalyst or its carrier.

Petrochemical product refining: It is used to remove aromatic hydrocarbons and can also be applied for selective adsorption and separation of organic gases and liquids.

Moisture prevention and drying applications: Used for dehydration and purification of industrial gases, as well as moisture-proof packaging, delivering excellent drying performance.

Insulating oil purification: Wide pore silica gel can effectively remove organic acids and polymers in insulating oils, improving oil quality.

Industrial fermentation purification: During the fermentation process, wide pore silica gel adsorbs high-molecular proteins, thereby increasing the purity of the product.

Water treatment: Used in ion exchange processes to remove multivalent harmful elements from water.

To maintain the optimal performance of wide pore silica gel, it must be stored and transported properly:

It should be stored in a ventilated and dry warehouse, avoiding moisture exposure.

It should not be stored or transported together with volatile substances.

During transportation, care should be taken to avoid damage to the packaging containers.

As an excellent adsorbent material, wide pore silica gel plays a crucial role in fields such as chemical, petrochemical, and environmental protection industries. Its high safety, ease of use, and adaptability make it an indispensable material in numerous industrial applications. In the future, as technology advances, wide pore silica gel will demonstrate even greater potential in more high-end applications.